Campaign

September 17, 2024

Steam Types and Usage Areas

Process Steam

The steam produced in boilers for indirect heating in processes is referred to as operating steam or facility steam. This type of steam contains chemicals or additives, so it cannot be considered “clean” for the process. When using operating steam in indirect heating processes, the material exposed to the steam is not suitable for use due to the chemicals it contains. For example, operating steam should not be used for direct heating in the food industry because the substances it contains can affect the "safety" of food products from a public health perspective. Therefore, clean steam is required for such applications.

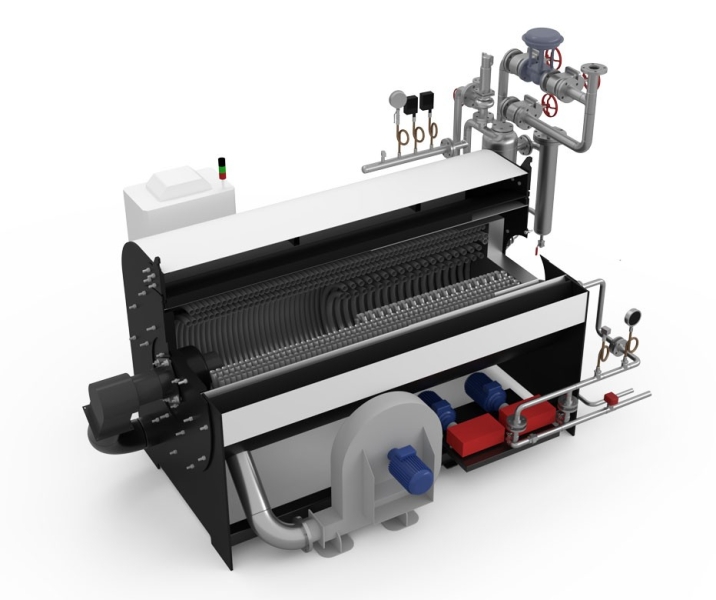

Hygienic Steam

Hygienic steam generators produce "pure" and "clean" steam. These machines are used in situations where the steam must be free from harmful and foreign substances. They are often found in the food, cosmetic, pharmaceutical industries, and in processes involving steam sterilization.

Hygienic steam is also used not only in the pharmaceutical industry and hospitals but also in food cooking, processing, and sterilizing food and beverage containers.

The production method for hygienic steam is specified by international standards.

- Filtered Steam: Produced from operating steam using a very fine filter defined by microns. This type of clean steam is generally produced by filtering out particles larger than 2 microns, excluding water droplets of 2 microns and smaller.

- Clean Steam: Produced by a steam generator using deionized feed water. The system derives its heat from operating steam. Clean steam contains a minimal amount of chemicals, and limited chemical use in the feed water is permitted.

- Pure Steam: Obtained by using distilled or deionized water suitable for injection. Pure steam should not contain any chemicals. Despite the different substances involved in each type of clean steam production, all three are generally referred to as "Clean Steam."

Examples of Clean Steam Use:

- Sterilization: In the pharmaceutical industry and hospitals for sterilizing various equipment, containers, and textiles, as well as in the food and beverage industry.

- CIP (“Cleaning in Place”) and SIP (“Sterilization in Place”) Units: In pharmaceutical and food industries.

- Climate Processes: Clean steam is used to humidify the climate systems in clean rooms.

- Pharmaceutical Production: In the production of medicines and intermediates, and in the final cleaning of equipment.

Clean Steam System Requirements:

The distribution of steam should consider the efficient removal of condensate. Condensate removal is even more crucial in clean steam lines. This is because the system is designed to accumulate conditioning water, which forms condensate. Therefore, the following points should be used in the design of steam systems:

- Select the pipe diameter based on pressure, speed, steam quantity, and process entry conditions.

- Choose an average speed of 25 m/s for pipe diameter selection.

- Steam distribution should always be from the top. Take branch lines from the top. Use an appropriate type of condensate trap to drain condensate accumulating at the bottom of vertical risers.

- Provide a slope of 1/70 – 1/100 for the piping.

- Clean steam systems should be independent of utility steam. They should be designed as a completely separate system.

Clean steam is necessary in the pharmaceutical industry, food industry, and hospitals. The clean steam production system and steam distribution devices are crucial. Therefore, hygiene should be emphasized everywhere.

The design of hygienic steam generators and systems differs from that of standard operating steam generators and distribution pipes. Additionally, the equipment should be made of stainless steel and materials suitable for clean steam.

Furthermore, the quality of medical hot steam will affect the effectiveness of steam sterilization. Steam should not be 95% dry nor excessively superheated.