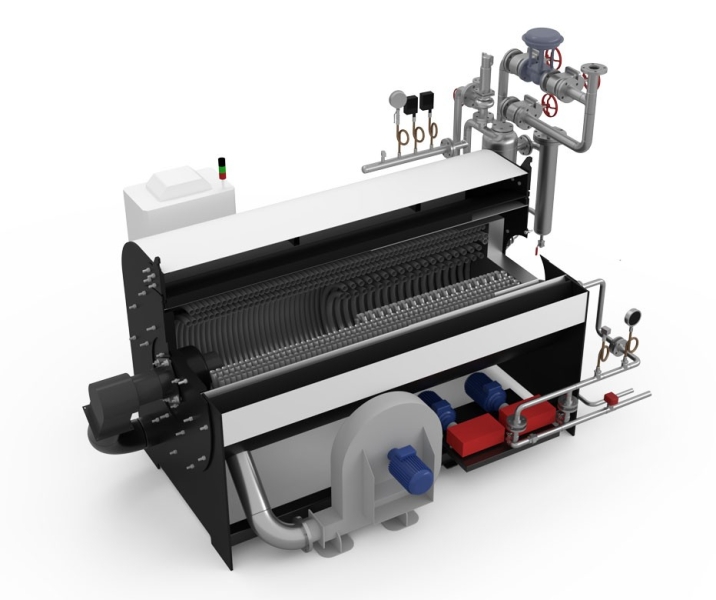

Cylinder Ironers

Rotating Cylinders – Cylinder Ironers

In drum machines, the heated cylinders are generally rotating cylinders, and the same applies to your machine.

Steam enters the cylinder and condensate is discharged through a steam head – coal (rotary joint). Condensate is normally expelled through a fixed siphon.

To maintain the correct temperature on the cylinder surface, steam pressure must be precisely controlled and condensate should be discharged as soon as it forms.

Several factors influence the characteristics of condensate inside a rotating cylinder:

- Cylinder diameter,

- Machine speed,

- Amount of condensate,

- Depth of the condensate film inside the cylinder,

and others.

Depending on these factors, condensate inside the cylinder behaves in one of three ways: “puddling,” “cascading,” or “rimming.”

Fixed Cylinder Puddling

Cascading Rimming

Siphons inside the cylinder generally succeed in draining condensate in the “Puddling” and “Cascading” forms.

In faster machines, the siphon may not effectively remove condensate in the “Rimming” condition, leading to water remaining in the cylinders and preventing them from heating properly.

As a result, operators are forced to reduce the machine’s rotation speed.

Reduced machine speed in slower operations can lead to decreased production and financial losses for the business.

In fast rotating cylinders like drums, large amounts of push steam are required to aid the flow of condensed steam through the siphon tube.

In such cases, a needle valve placed on the bypass line can be used to ensure effective expulsion through purging.